Monday, February 10, 2020

Friday, July 5, 2019

Sunday, February 10, 2019

Sunday, November 4, 2018

Sunday, February 5, 2017

Monday, February 1, 2016

You Need To Vent (Or Do you)?

Like

so many hoodlums wearing hoodies in the 'hood, many commercial

cooking devices masquerade as ventless appliances.

In breathless whispers, their marketers try to hoodwink us into believing that all are altruistic Robin Hoods - removing effluent from the bad air and giving forth good air ("just follow the blue arrows on the diagrams").

An exhaustive search of the available technologies would yield relatively few that truly could be classified as a ventless cooking apparatus in the first place. Many perform the heating function, rethermalizing pre-cooked foods with conducted energy, microwaves, steam and the like. Others can finish par-cooked products - melting, toasting, and/or caramelizing.

Typically only electric-powered equipment with their lack of attendant products of combustion can respire comfortably in this space. Grease-laden vapors, effluent, odors, particulate and condensate all must be mitigated through mechanical means. Mandatory too, fire suppression must be addressed. Catalytic converters, charcoal and specialty filters, precipitators, ionizers, et al provide the mojo "under the hood" of many of these modern marvels.

Now, take a deep breath: duct-season is over.

Certain mini combi ovens use a blend of the above technologies to provide bona-fide ventless primary cooking, allowing operators to prepare a varied menu including whole muscle proteins (from raw to finish)!

Deep fryers with mechanisms that automatically dispense product are self-contained, with fire suppression and extensive filtration on-board .

Slow cookers such as cook and hold ovens and water circulators for sous vide (due primarily to the low temperatures involved) require little attention to ventilation issues.

OK, now exhale a sigh of relief, from Hood Brook ME to Mt. Hood OR, you can find opportunities for ventless commercial kitchens. Now I'm exhausted.

In breathless whispers, their marketers try to hoodwink us into believing that all are altruistic Robin Hoods - removing effluent from the bad air and giving forth good air ("just follow the blue arrows on the diagrams").

An exhaustive search of the available technologies would yield relatively few that truly could be classified as a ventless cooking apparatus in the first place. Many perform the heating function, rethermalizing pre-cooked foods with conducted energy, microwaves, steam and the like. Others can finish par-cooked products - melting, toasting, and/or caramelizing.

Typically only electric-powered equipment with their lack of attendant products of combustion can respire comfortably in this space. Grease-laden vapors, effluent, odors, particulate and condensate all must be mitigated through mechanical means. Mandatory too, fire suppression must be addressed. Catalytic converters, charcoal and specialty filters, precipitators, ionizers, et al provide the mojo "under the hood" of many of these modern marvels.

Now, take a deep breath: duct-season is over.

Certain mini combi ovens use a blend of the above technologies to provide bona-fide ventless primary cooking, allowing operators to prepare a varied menu including whole muscle proteins (from raw to finish)!

Deep fryers with mechanisms that automatically dispense product are self-contained, with fire suppression and extensive filtration on-board .

Slow cookers such as cook and hold ovens and water circulators for sous vide (due primarily to the low temperatures involved) require little attention to ventilation issues.

OK, now exhale a sigh of relief, from Hood Brook ME to Mt. Hood OR, you can find opportunities for ventless commercial kitchens. Now I'm exhausted.

Labels:

Pecinka Ferri,

restaurant equipment,

ventless

Sunday, November 1, 2015

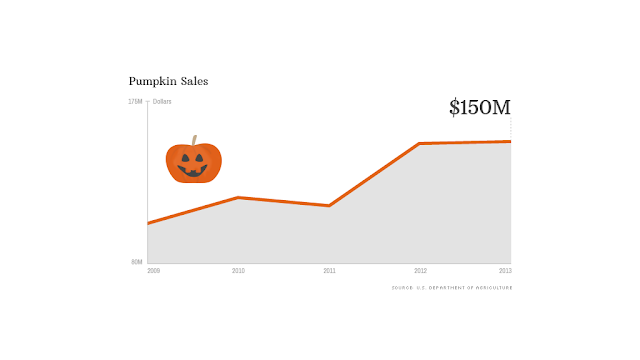

🎃 A Frightening Visit 🎃

The haunted hayride from the airport to our first

appointment led me to be believe that everything the sales mangler needed to

know was learned by trick-or-treating.

From his inappropriate costume, to his empty tote, he was ill-prepared

for the horrors that awaited him at the dealerships.

Our pumpkin-headed protagonist had one goal in mind: to

procure treats (purchase orders). He

would not stand for accepting tricks (service issues).

Of all of the witches, Frankensteins, mummies and ghouls,

perhaps the scariest of all of the apparitions coming to town is the

werewolf. You remember him don’t

you? No, not Jack (O’Lantern, we’re

talking about the fellow who morphs from one creature when with you, and into

another one when in front of a customer).

Why do we continue to drink the same Kool-Ade each year and

expect different results?

The time has come for a new strategy: pre-plan the dreaded

territory visit!

A few key questions answered in advance could eliminate the

horrifying confusion and fear.

Who, what, when, where, and why? Establishing the logistics before the

bewitching hour could go a long way in successfully navigating the bell-ringing

before the neighborhood curfew is up.

Will there be training?

What collaterals are needed? Is there a new product to be focused on?

Any particular geographic area or customer class that needs attention? Who’s making the lodging and entertainment

reservations? Are there any skeletons in

the closet?

Having ironed out all of the particulars beforehand will go

a long way in setting priorities and expectations on everyone’s parts. Measuring the results against those

pre-established goals represent the essential tools for gauging the success of

a field excursion.

Accepting candy from strangers is only advisable one day per

year. Actively managing your

relationships should not be an ongoing nightmare.

Subscribe to:

Comments (Atom)